开放建筑理念的百年住宅设计与实践研究——以南京江北新区人才公寓3号楼为例-bobty登录入口

【导读】“ 第20届中日韩居住问题国际会议”圆满落幕。为了更好的分享学术成果,近期本公众号将陆续刊载会议论文。本期刊载的是“第1子专题:装配式住宅的多类型建筑技术与居住环境”中方优秀论文,中文摘要及英文全文如下:

1 前言

20世纪80年代初期,伴随着中国城市化建设,为解决住房严重短缺而推行的住房商品化改革,国内开启了开放建筑论研究与实践的时代。清华大学张守仪教授首次将支撑体理论和方法介绍到我国,东南大学鲍家声教授系统地研究了sar住宅理论和设计方法,对住宅的标准化、多样化及其灵活适应性进行了实践上的探索。

随着时代发展,人民对住房的品质和质量要求不断提升,倪虹部长提出“从好房子到好小区,从好小区到好社区,从好社区到好城区,让城市更宜居、更韧性、更智慧”。南京江北新区人才公寓3号楼基于开放建筑理念和新时代住房发展需求开展百年住宅设计实践,以建设产业化、建筑长寿化、品质优良化、绿色低碳化为目标,系统整合装配、绿色、健康、智慧技术,建设新时代建筑示范项目和创新探索面向未来的“好房子”样板。

2 项目概况与设计理念

江北新区人才公寓面向江北新区及南京市各类人才提供租赁住宅,3号楼位于小区西南角,总高度96.45m,地上建筑面积为2.28万m2,是江苏省首栋装配式组合结构居住建筑,先后获得绿色建筑三星级、健康建筑三星级设计标识。该项目同时被列为2018年度住建部、江苏省、南京市装配式建筑示范项目。

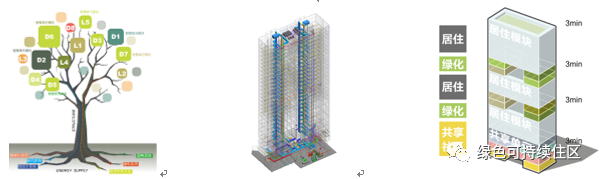

项目以“智慧树”为理念,将生物概念植入模块,核心筒犹如一棵智慧树的主干和根,采暖、供水、供电等系统都集中在核心筒和地下室,各功能房间就像枝干和树叶,在智能主干的基础上插入更多智慧单元模块的可能性。树干本身的设计具有极大的灵活度,为智慧单元的植入和毛细血管构建提供综合服务和管网智慧接口,所有植入部分都在主干基础上尽可能实现人工智能。

项目倡导“共享”的理念,通过高度的集约化与智能化,营造丰富共享业态和交流场所,赋予居住空间更多可能性。

3 科技创新点

3.1 装配式技术体系全面性、系统性应用

项目全面综合应用了装配式建筑四大系统,采用装配式内外墙围护系统、装配式混合结构系统、装配式内装技术、分离式设备管线系统,实现了装配式建筑技术全面、系统性创新应用,装配率达80.8%。

(1)建筑设计

项目将建筑造型与预制装配技术融合创新,按照工业化建筑“少构件、多组合”的思维,采用了标准化规划与设计、平面标准化、户型标准化、立面标准化等设计手法,最大限度地提高效率降低成本,充分发挥工业化建造建筑的优势。采用可变建造技术体系、集成化核心筒设计,利用标准化设计的手法灵活布置户型,提供多种可能性。

(2)结构设计

根据百年住宅的核心思想,结构设计从全生命周期出发,在结构布置考虑适应使用年限内功能的变化,同时用材方面考虑绿色低碳,并保证结构安全性能和主体耐久性。

(3)装配化装修设计

项目采用装配化装修建造体系(csi体系),从而达到百年住宅建造要求。墙面、顶面、地面装饰面与主体结构分离,实现可变、可更换;管线系统与主体结构分离实现管线技术可持续改造及围护。

3.2 装配式技术与绿色健康技术集成应用

项目实现了预制装配式技术与绿色健康建筑技术整合创新应用,包括:空中花园、保温隔热设计、太阳能光伏一体化、地源热泵、太阳能与空气源热泵热水、雨水回收利用、空气净化与直饮水等技术。整栋建筑太阳能光伏总装机容量为45kw,有效提升大楼的可再生能源利用率。

3.3 未来绿色智慧科技住宅

项目采用科技智慧体系,建立以数据为核心,用户需求为导向的智慧建筑平台。通过各类智能化系统让小区安全性更高、生活更便利、管理更高效,同时更加节能环保,提高了小区的附加值,提升了生活品质。

4 实践总结

南京江北新区人才公寓3号楼试点项目集成了当下住宅领域的多项领先技术,从设计到建造,实现了百年住宅所提出的各项指标要求和示范性目标。项目不仅为行业提供了一个可以观摩、交流和感受的“好房子”样本,也代表了新时代绿色、低碳、宜居、智慧住宅建设的发展方向。同时为当前艰难转型的住房市场提供了重要的启示:品质为基,创新为王,方能在高质量发展的道路上行稳致远。

英文全文

01

introduction

in the early 1980s, with the urbanization construction in china, the housing commodification reform was implemented to address the severe shortage of housing. this marked the beginning of an era of open architectural research and practice. focusing on the standardization and diversification issues present in a large number of residential buildings during the early stages of reform and opening-up, professor shou-yi zhang from tsinghua university introduced the concept of supporting structure theory and methods to china for the first time in the journal of architecture. professor jia-sheng bao from southeast university systematically researched sar residential theories and design methods. he published a monograph titled “supporting structure housing” and conducted practical explorations on the standardization, diversification, and flexible adaptability of residential buildings.

as the times evolve and society progresses, people’s longing for a better life becomes stronger. the demands for quality and standards in housing continue to rise. minister hong ni proposes the concept of “from good houses to good neighborhoods, from good neighborhoods to good communities, from good communities to good urban areas, making cities more livable, resilient, and intelligent.” based on the concept of open architecture and the development needs of housing in the new era, building 3 of the talent apartments in nanjing jiangbei new district conducts a century-long residential design practice. with the goals of industrialization, long life span, excellent quality, and green and low-carbon development, the project systematically integrates assembly technology, green technology, health technology, and smart technology. it strives to build a model project for the new era of architecture and an innovative exploration of future-oriented “good houses”.

02

project profile

the talent apartment project in jiangbei new district is located in the core area of nanjing’s jiangbei new district. it consists of public rental housing and provides leased residences for various talents in jiangbei new district and across nanjing city. building 3 is situated in the southwest corner of the community. it has one underground floor and 28 above-ground floors, with a standard floor height of 3.3 meters from the 7th to the 28th floor. the total height of the building is 96.45 meters, and the total above-ground floor area is 22,800 square meters. the project is designed and constructed in accordance with the requirements of the “design and assessment standard for long-life sustainable housing”. it is centered around the principles of “green, healthy, smart, long-lasting, and humanistic” design concepts to comprehensively enhance the quality and standard of the project in areas such as the si building system, longevity performance of the building, excellent quality performance, and green sustainability. it aims to create a high-quality human settlement complex that is green, low-carbon, durable for a century, dynamically updated, and smartly livable throughout its entire lifecycle. it strives to promote the future concept and culture of green and shared living, emphasizing sustainability and the well-being of its residents.

this project is the first modular composite structure residential building in jiangsu province. it has received the designations of three-star green building and three-star healthy building.

figure 1: the scenes of block 1 and building 3 of the jiangbei new district talent apartments

03

design concept and plane function

3.1. design concept

the project takes the concept of the "smart tree" and conducts research and practice on a century-long future technology system. it treats the building as an "organism" and incorporates biological concepts into modules. the core shaft is like the trunk and roots of a smart tree, with heating, water supply, power supply, and other systems centralized in the core shaft and basement. the functional rooms are like branches and leaves, with the possibility of inserting more smart unit modules on the basis of the intelligent trunk. the design of the trunk itself has great flexibility, providing comprehensive services and intelligent network interfaces for the implantation and construction of capillary-like smart units. all implanted parts strive to achieve artificial intelligence based on the trunk.

the project advocates the concept of “sharing” and creates a highly intensive and intelligent environment to cultivate diverse shared formats and exchange spaces, providing residential spaces with more possibilities.

figure 2: the concept of smart tree and shard design

3.2. plane function

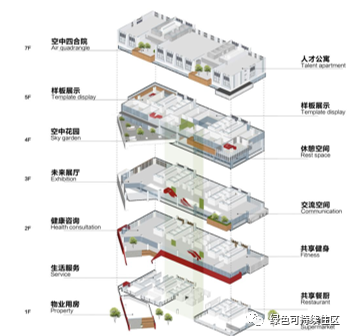

this project incorporates different types of residential apartments, sky gardens, shared fitness facilities, shared offices, commercial services, and elderly care services into an open vertical space, achieving functional complexity and diversity within the vertical space. residents can enjoy modern conveniences without leaving the building. the overall architecture is divided into two main areas: floors 1 to 6 consist of shared public spaces, which include a variety of public service formats, maker spaces, and exhibition areas. floors 7 to 28 offer flexible residential spaces, providing diverse living options for different needs.

figure 3: the functional zoning of the public areas on floors 1 to 6 of the building

04

technological innovation points

4.1. the comprehensive and systematic application of prefabricated technology

the project comprehensively and comprehensively applied the four major systems of prefabricated construction, including the prefabricated external and internal wall enclosure system, the prefabricated hybrid structure system, the prefabricated interior technology, and the detached equipment pipeline system. this achieved a comprehensive and systematic innovation application of prefabricated construction technology, with a prefabrication rate reaching 80.8%.

4.1.1. architecture design

the project combines architectural aesthetics with prefabricated assembly technology, following the concept of “fewer components, more combinations” in industrialized construction. the architectural facades are designed with standardized and modular principles, using standardized basic components for assembly.

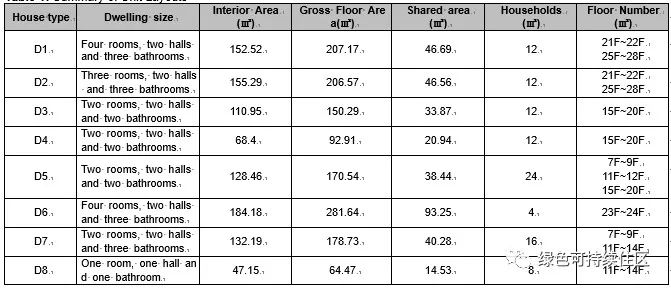

plan modular designmodular design is adopted for the building floor plan, incorporating techniques such as standardized planning and design, standardized floor layouts, standardized unit layouts, and standardized facades. these design approaches maximize efficiency and cost-effectiveness, fully leveraging the advantages of industrialized construction. the high-rise buildings utilize 8 types of unit layouts combined into 4-unit forms, providing necessary conditions for later individualized and standardized design. this approach not only reduces construction costs but also improves unit diversity, as shown in table 1.

table 1: summary of unit layouts

modular facade designthe residential facade adopts industrialized processing techniques, using standardized grc (glass fiber reinforced concrete) module components. the dimensions of the components are modularized, and they are assembled in units of two floors, creating a futuristic and prefabricated effect. the uniform floor height of the residential units enables efficient quantified production of prefabricated components, facilitating the rapid implementation of modular construction techniques. this design also allows for easy disassembly and replacement after a certain period of use, achieving a variable facade.

figure 5: prefabricated concrete external cladding panels for the north facade and east-west mountain walls

adaptive construction technologyadopt an adaptive construction technology system. considering the mobility and rental characteristics of the residents, the unit design is based on standardization, modularization, and variability as design principles. the floor plans can be divided and combined. taking future housing as an example, the basic module for the floor plan axis dimension is set at 7.8m. various flexible layouts of unit types are arranged around the standardized core. the spatial division of unit types is based on a module of 3, allowing for flexible arrangement using standardized design techniques, providing multiple possibilities.

integrated core designutilize an integrated core design where all vertical pipeline systems (water, electricity, ventilation, fresh air, etc.) for the building are integrated around the core, while only horizontal pipelines are installed within the units. this facilitates the reconfiguration and combination of unit types. at the same time, the width of the core is coordinated with the residential section to ensure the modularity and coordination of the external cladding panels.

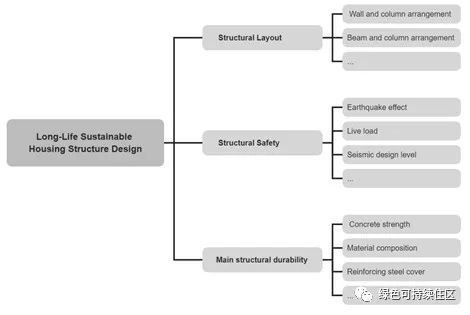

4.1.2. structural design

long-life sustainable housing structural designthis project is a long-life sustainable housing. based on the core principles of a long-life sustainable housing, the structural design takes into consideration the changes in functionality throughout the entire lifecycle. the material selection prioritizes green and low-carbon options while ensuring structural safety performance and long-term durability. the structural design concept is illustrated in figure 6.

figure 6: long-life sustainable housing structural design concept

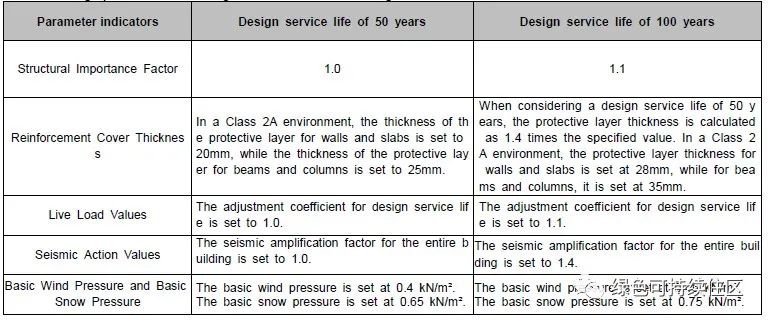

compared to residential buildings with a design lifespan of 50 years, parameters need to be adjusted for a hundred-year residential building, as shown in table 2.

table 2: design parameters for long-life sustainable housing

structural layoutthe core shear walls are constructed with cast-in-place reinforced concrete shear walls. the foundation utilizes a piled raft foundation. the columns are made of rectangular steel tube concrete columns and steel-concrete composite columns. the steel beams adopt welded h-shaped steel beams and are connected using bolted-welded rigid connections in cantilevered sections. when necessary to achieve “strong column, weak beam,” measures such as adding welded cover plates and using dog-legged beam end connections can be taken. h-shaped steel beams are connected to h-shaped steel beams using bolted-welded rigid connections. rectangular steel tube concrete rigid column bases are used.

precast concrete curtain wall panels

precast concrete curtain wall panels are used for the north facade and the perimeter structural enclosure of the two side walls. the exterior wall panels are classified into enclosure board systems and decorative board systems based on the functional requirements of the building facade. the enclosure board system can be further divided into whole-panel systems, strip-board systems, and vertical-strip board systems based on the characteristics of the building facade. typically, the whole-panel system is suitable for panel widths (b) ≤ 6.0m and panel heights ≤ 5.4m; the strip-board system is suitable for panel widths (b) ≤ 9.0m and panel heights ≤ 2.5m; the vertical-strip board system is suitable for panel widths (b) ≤ 2.5m and panel heights ≤ 6.0m.

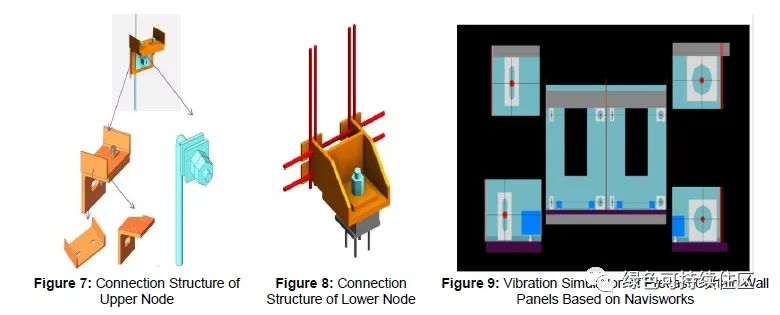

considering the architectural functional requirements, window openings, standardization and modularization, ease of component transportation, rational load distribution, as well as ease of fabrication and installation, the wall panels are arranged and divided, and the whole-panel system is chosen.the connection between the translatable precast concrete curtain wall panel and the main structural steel beam is divided into load-bearing nodes and non-load-bearing nodes. the upper node is a non-load-bearing node, and its connection structure is illustrated in figure 7, which allows for relative displacement between the upper node of the precast concrete curtain wall panel and the main structure. the lower node is a load-bearing node, and its connection structure is shown in figure 8. this structure accomplishes the hinged connection between the precast concrete curtain wall panel and the steel beam. through navisworks simulation and vibration table experiments conducted by tongji university, the design expectations were achieved (see figure 9).

4.1.3. assembled interior design

based on the overall design principles of the residential area, the project adopts a assembled interior construction system (csi system) to meet the requirements of constructing a century-long residence. as shown in figure 10, the decorative surfaces of the walls, ceilings, and floors are separated from the main structure, allowing for variability and replacement. the pipeline system is also separated from the main structure to enable sustainable remodeling and enclosure of the pipeline technology.

figure 10: comprehensive and systematic innovative application of assembled interior technology

raised floor

by using a raised floor, the arrangement of cables and wires can be changed as needed, reducing the need for embedded conduit systems for comprehensive wiring. customized modules with foot supports are used to accommodate plumbing and electrical pipes in the raised floor area, and adjustable floor bolts provide strong adaptability to floor deviations ranging from 0 to 50mm.

modular suspended ceiling

prefabricated gypsum board suspended ceilings are utilized, offering both decorative effects and good sound absorption performance.

lightweight and fast-installed integrated wall system

the internal partition walls are constructed using 90mm lightweight calcium silicate composite insulation wall panels, while the walls between units are built with 200mm calcium silicate composite insulation wall panels. these walls meet the requirements for sound insulation and thermal insulation, and the hollow cavities can integrate pipelines, making them easy to replace and maintain.

integrated bathroom

integrated bathrooms are employed with a thin floor same-level drainage system. the bathroom floor height is only 150mm, and an integral waterproof chassis is used. with the thin floor same-level side drain, drainage pipes are arranged beneath the raised floor, eliminating height differences with other rooms.

integrated kitchen

integrated kitchen modules are adopted, which benefits large-scale industrial production and reduces procurement costs. a standardized cabinet system ensures unified collaboration for various functions such as operation and storage, achieving both functional completeness and aesthetic space.

4.2. integrated application of modular technology and green health technology

the project has achieved integrated innovative application of prefabricated modular technology and green health building technology, including the following technologies: garden in the air, thermal insulation design, integration of solar photovoltaics, ground source heat pumps, solar and air source heat pump hot water systems, rainwater harvesting, air purification, and direct drinking water. the project meets the standards of a three-star green building and a three-star healthy building.

figure 11: garden in the air

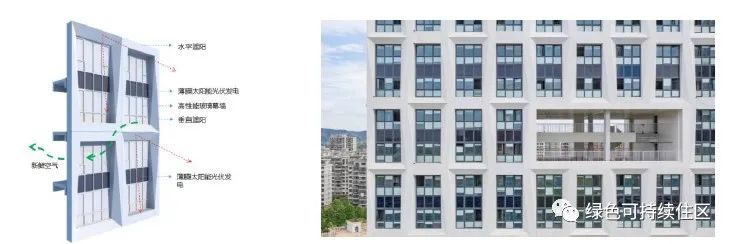

the south elevation of the structure utilizes an industrialized thin-film solar photovoltaic skin (figure 12) for the grc exterior walls. the unique facade forms an efficient shading system by taking advantage of the high solar altitude during summer. it reflects most of the sunlight during summer while utilizing the principle of lower solar altitude during winter to introduce a significant amount of sunlight into the interior. the total installed capacity for solar photovoltaics in the entire building is 45kw, effectively enhancing the renewable energy utilization of the building.

figure 12: integrated design of solar photovoltaic power generation

4.3. future green, intelligent technology residences

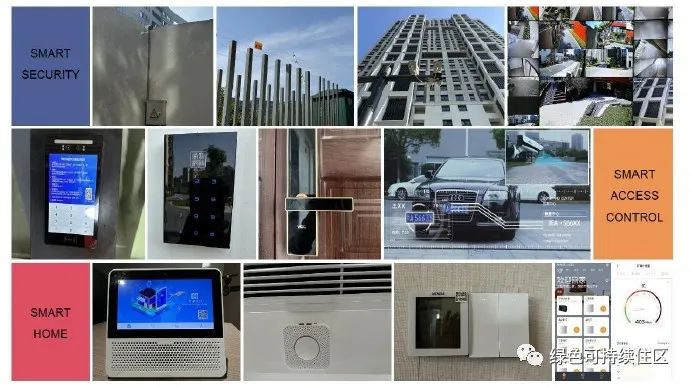

the project also adopts a technological smart system, establishing an intelligent building platform centered around data and guided by user needs. as shown in figure 13, the main intelligent systems designed for this project include: intelligent security system, smart home and home alarm system, smart door lock system, building equipment management system, remote meter reading system, environmental sensing system, and data center engineering, among others. through various intelligent systems, the community’s security is enhanced, daily life becomes more convenient, and management becomes more efficient. at the same time, it improves energy efficiency and environmental protection, increases the added value of the community, and enhances the quality of life.

figure 13: integration of technological smart systems

based on the comprehensive application of various intelligent information, it integrates the combination of structure, system, application, management, and optimization. it possesses comprehensive intelligence capabilities of perception, transmission, memory, judgment, and decision-making. it provides people with a secure, efficient, convenient, and sustainable building functional environment.

05

conclusions

the pilot project of building 3 in nanjing jiangbei new district talent apartment integrates multiple leading technologies in the current residential field, achieving the requirements and exemplary goals proposed for century-old residences from design to construction. the project not only provides the industry with a “good house” sample that can be observed, exchanged, and experienced but also represents the development direction of green, low-carbon, livable, and intelligent residential construction in the new era. at the same time, it provides important enlightenment for the current challenging transformation of the housing market: the foundation lies in quality, and innovation is paramount to ensure steady and far-reaching progress on the path of high-quality development.

references

liu dongwei, zhou jingmin. residential design and practice in the theory of open building[m]. beijing: china architecture & building press, 2021.

qin shan, liu dongwei, wu zhichao. integrated design and construction of residential building systems in the sustainable development model: theoretical methods, system technology research and practice of century-long residential construction in china[j]. journal of architecture, 2020, (05): 32-37.

zhu kan, zhao xuefei, pei xiaoming. exploration and practice of high-rise variable residential design: a case study of talent apartments in nanjing jiangbei new area[j]. huazhong architecture, 2020, 38(09): 38-42.

liu zhifeng. implementing the scientific outlook on development and constructing century-long residences in china[j]. residential industry, 2010(5): 15-16.

本文作者:

王兰桥,南京长江都市建筑设计股份有限公司、科研助理、建筑师

汪 杰,南京长江都市建筑设计股份有限公司,董事长、研究员级高级工程师

韦 佳,南京长江都市建筑设计股份有限公司,科研部经理、研究员级高级建筑师

赵学斐,南京长江都市建筑设计股份有限公司、副主任工程师、高级工程师